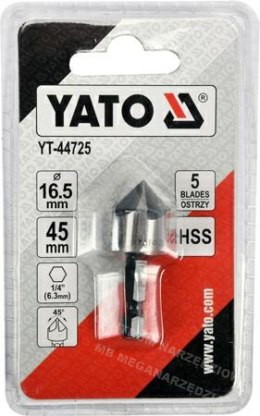

MILWAUKEE Cobalt HSS Countersink 10.4mm – High Precision & Durability

The MILWAUKEE HSS countersink with cobalt is a tool designed for precise deburring and countersinking. Made in accordance with DIN 335C, with a 90° angle, it provides exceptional accuracy and work efficiency. Three cutting edges and optimized cutting geometry facilitate centering, efficient chip evacuation and vibration reduction. Thanks to its cobalt content, the countersink has a 50% longer life compared to standard HSS tools, making it an ideal choice for working with difficult materials such as stainless steel, cast iron, aluminum, and plastics.

Product Highlights

- ✅ DIN 335C standard: The tool meets the highest quality standards for precise and reliable countersinking.

- ✅ Three cutting edges: enable deburring and countersinking in one go, in accordance with DIN 74/75.

- ✅ Optimized cutting geometry: ensures easy centering, efficient chip removal and minimized vibration.

- ✅ High durability: Thanks to the cobalt content, the tool offers a 50% longer service life compared to standard HSS countersinks.

- ✅ Wide range of applications: suitable for machining steel and stainless steel < 1100 N/mm², cast iron, aluminium and plastics.

- ✅ Recommendations for use: for the best tool life, it is recommended to use grease during operation.

Use and benefits

The MILWAUKEE HSS cobalt countersink is a reliable tool for precision countersinking and deburring of holes, ideal for industrial and workshop applications. Thanks to its exceptional durability and efficiency, this tool is perfect for working with demanding materials such as stainless steel or aluminum. The optimized cutting geometry and the three cutting edges guarantee smooth and precise work, while reducing the pressure force.

Technical data

| Diameter |

10.4 mm |

| Material |

HSS with cobalt |

| Standard |

DIN 335C |

| Angle |

90° |

| Use |

Steel, stainless steel, cast iron, aluminum, plastics |

0

arts

0

arts

![[{[item.product.name]}]]([{[item.product.photo.url]}] 125w)